When you have a complex product or process that requires special handling such as:

- moving product up steep inclines or down sharp declines

- maintaining product separation

- minimising points of contact

- keeping the product aligned in rows

- maintaining a flat belt surface in high temperature or inverted applications

That’s when you need a belt that can accommodate your process’s difficult handling requirements. You need a specialty belt from Wire Belt Company.

Specialty belts are custom-designed and manufactured to your exact specifications by our team of experienced Engineers. You will have the confidence that you are working with the leading company that has been engineering and manufacturing these types of belts for over 70 years.

We design and manufacture these types of belts for such diverse applications as: automotive brake pads, electronic circuit boards, chocolates, bagels, fried snack foods and many other applications. Our Engineering team looks forward to tackling your challenging application and finding the right solution to fit your needs.

Aligned Flat-Flex® speciality conveyor belts:

Keep product in specific rows

Aligned belts are used to convey products in specific rows. These belts utilise rows of flights to control and separate delicate products while minimizing damage and waste. In this configuration, all strands are formed in the same manner throughout the belt length. However, the number of rows and the spacing can be varied. The height of these product guides are available up to 12.7mm depending on the belt mesh.

Aligned belts convey products in specific rows

Aligned belts utilise rows of flights (highlighted) to permit control and separation of delicate products

Front view of products separated into defined rows

Compound Flat-Flex® conveyor belts

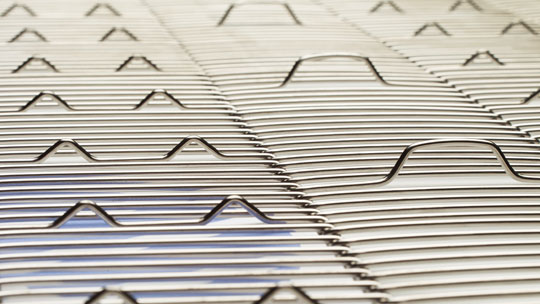

Compound conveyor belts incorporate specially formed strands with raised sections called "flights" in predetermined locations in the basic flat belt. These are typically used to help move product up an incline, down a decline, or to support, separate or minimize contact between products. The pattern of flights can be designed to create “pockets” that totally isolate easily damaged products. Flights are available in four standard forms from 3mm up to 25mm high/deep.

Flight in the belt makes it possible to move product up steep inclines or down sharp declines

The pattern of flights (highlighted) can be designed to create “pockets” that isolate easily damaged product

Compound belts can also incorporate flights to help support delicate products such as circuit boards

Crowned and Reverse-Crowned Flat-Flex® conveyor belts

Crowned Belts

Since belts may curl when subjected to high temperature, belts can be supplied with a camber introduced. This pre-stresses the belt in the opposite direction to maintain a flat surface during operation.

Reverse-Crowned Belts

These belts are used for hold down applications, such as the conveyorised frying process. Running inverted above the product and supported by its edges, this prevents the belt from sagging.