Eye-Flex® has almost limitless options and its configurations are custom designed to meet your requirements. For product orientation, Eye-Flex® offers flights and side guards to meet all product handling needs. Additionally, Eye-Flex® is available with multiple drive options including cage rollers, positive drive sprockets, and an optional chain edge drive for enhanced tracking and reliability.

Advantages of Eye-Flex® include

- Flat carrying surface

- Easy to clean due to open construction

- Positive drive

- High load capacity

- Modular design

- Almost unlimited application possibilities

Eye-Flex’s high strength, robustness and open, flat carrying surface provide the answer to your heavy duty conveyor belt requirements.

Many elements of Eye-Flex® belt can be customised to suit each individual application, such as gap width and fixing method:

- Normal gap

- Ring

- Spring

- Distance sleeves

- Underwelded wire

Optional Features

- Side chains, hollow pin or loose link chain

- Side guards

- Cross flights

Typical Applications

Transport

Cooking

Heating

Drying

Coopng

Coating

Drainage

Freezing

Enrobing

Frying

Baking

Washing

Weed Clearing

Curing

Sorting

Dredging

Elevating

De-Elevating

Loading

Degreasing

Grading

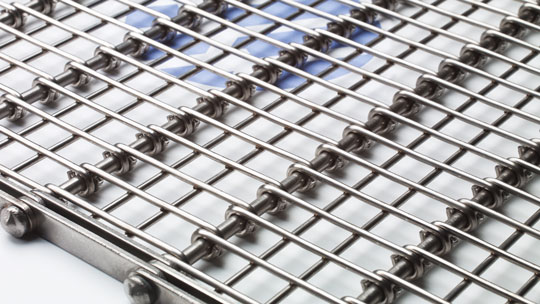

Eye-Flex® belt without spacers

Eye-Flex® has a standard construction based on a straight modular form.

It is designed and built without spacers or perpendicularly welded under wires. This allows excellent flow-through in applications where no cross support is required. Eye-Flex® is often used in food processing for its flat conveying surface, open mesh configuration, and ease of cleaning. Eye-Flex® without spacers is also easily repaired with minimal cost.

Eye-Flex® belt without spacers |

||||||

| Belt Pitch mm | Wire Dia. mm | Cross Rod Dia. mm | Belt Pitch mm | Wire Dia. mm | Cross Rod Dia. mm | |

| 15.875 | 1.80 | 3.20 | 50.00 | 3.00 | 5.00 | |

| 25.00 | 2.00 | 5.00 | 50.80 | 1.60 | 8.00 | |

| 25.40 | 2.00 | 5.00 | 50.80 | 1.60 | 6.00 | |

| 30.00 | 1.60 | 4.00 | 50.80 | 2.00 | 8.00 | |

| 30.00 | 2.00 | 4.00 | 50.80 | 2.50 | 8.00 | |

| 30.00 | 2.00 | 5.00 | 50.80 | 2.50 | 5.00 | |

| 30.00 | 2.00 | 7.00 | 50.80 | 3.00 | 5.00 | |

| 30.00 | 2.00 | 8.00 | 50.80 | 4.00 | 7.00 | |

| 31.75 | 2.00 | 5.00 | 60.00 | 2.00 | 5.00 | |

| 50.00 | 1.40 | 5.00 | 60.00 | 2.50 | 5.00 | |

| 50.00 | 1.60 | 5.00 | 70.00 | 4.00 | 7.00 | |

| 50.00 | 2.00 | 5.00 | 75.00 | 2.50 | 5.00 | |

| 50.00 | 2.50 | 6.00 | 75.00 | 2.50 | 8.00 | |

| 50.00 | 2.50 | 8.00 | 100.00 | 3.00 | 8.00 | |

Eye-Flex® belt with underwelded wire spacing

Eye-Flex® belting with underside welded wires

provide the largest range of available gap widths, up to 50mm. One, two or three wires can be welded to the underside of the links, depending on the belt pitch and application requirements. Underwelded wire spacing should be considered on applications where hygiene and sanitation are critical. The underwelded wire eliminates the potential bacteria traps under the spacers, springs, rings and sleeves. This configuration makes cleaning and sanitation easy and more efficient.

| Eye-Flex® belt with underwelded wire spacing | |||||

|---|---|---|---|---|---|

| Belt Pitch | Wire Diameter | Cross Rod Diameter | Minimum Gap Spacing | Gap in Steps of | Maximum No. of Welded Wires |

| mm | mm | mm | mm | mm | mm |

| 15.875 | 1.80 | 3.20 | 2.00 | 0.10 | 1 |

| 25.000 | 2.00 | 5.00 | 2.30 | 0.10 | 2 |

| 25.400 | 2.00 | 5.00 | 2.30 | 0.10 | 2 |

| 30.000 | 2.00 | 4.00 | 2.30 | 0.10 | 2 |

| 30.000 | 2.00 | 5.00 | 2.30 | 0.10 | 2 |

| 50.000 | 2.00 | 5.00 | 2.30 | 0.10 | 3 |

| 50.000 | 2.50 | 5.00 | 2.80 | 0.10 | 3 |

| 50.000 | 2.50 | 6.00 | 2.80 | 0.10 | 3 |

| 50.800 | 2.50 | 8.00 | 2.80 | 0.10 | 3 |

| 50.800 | 3.00 | 8.00 | 3.30 | 0.10 | 3 |

| 75.000 | 2.50 | 5.00 | 2.80 | 0.10 | 3 |

| 75.000 | 2.50 | 8.00 | 2.80 | 0.10 | 3 |

Eye-Flex® belt with rings as spacers

This versatile variation of Eye-Flex® uses rings

between the wires to increase the belt gap. By increasing the belt gap, more air will circulate around the bottom of the product. Increasing the product exposure to this additional air flow improves the efficiency of your process. The gap is set by one or more rings placed between adjacent links on the cross rod. The gap width is determined by the number and thickness of rings used.

| Eye-Flex® belt with rings as spacers | ||||||||

|---|---|---|---|---|---|---|---|---|

| Belt Pitch mm |

Wire Diameter mm |

Cross Rod Diameter mm |

Minimum Gap Spacing mm |

Gap Spacing can be increased by mm |

||||

| 25.000 | 2.00 | 5.00 | 4.00 | 2.00 | ||||

| 25.400 | 2.00 | 5.00 | 4.00 | 2.00 | ||||

| 30.000 | 2.00 | 4.00 | 4.00 | 2.00 | ||||

| 30.000 | 2.00 | 5.00 | 4.00 | 2.00 | ||||

| 31.750 | 2.00 | 5.00 | 4.00 | 2.00 | ||||

| 50.000 | 2.00 | 5.00 | 4.00 | 2.00 | ||||

| 50.000 | 2.50 | 5.00 | 5.00 | 2.50 | ||||

| 50.000 | 2.50 | 6.00 | 5.00 | 2.50 | ||||

| 50.800 | 2.50 | 6.00 | 5.00 | 2.50 | ||||

| 50.800 | 2.50 | 8.00 | 5.00 | 2.50 | ||||

| 50.800 | 4.00 | 8.00 | 8.00 | 4.00 | ||||

| 60.000 | 2.00 | 5.00 | 4.00 | 2.00 | ||||

| 60.000 | 2.50 | 5.00 | 5.00 | 2.50 | ||||

| 75.000 | 2.50 | 5.00 | 5.00 | 2.50 | ||||

| 75.000 | 2.50 | 8.00 | 5.00 | 2.50 | ||||

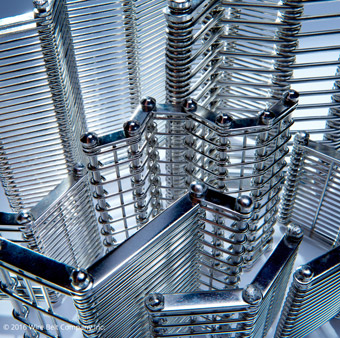

Eye-Flex® belt with springs as spacers

Springs help create a more dimensionally stable belt in heating or freezing applications.

These belts are more dimensionally stable because the wires are able to move on the cross rod. Springs also expose a large proportion of the connecting rod for improved cleaning and sanitising. The gap width is secured by springs placed on the cross rod between adjacent links. Permanent fixing of the wire links does not occur with this method. They are held in relative position by compression of the springs.

| Eye-Flex® belt with springs as spacers | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Belt Pitch mm |

Wire Diameter mm |

Cross Rod Diameter mm |

Minimum Gap Spacing mm |

Gap Spacing also Available in these Widths mm | |||||

| 25.000 | 2.00 | 5.00 | 7.00 | 8.00 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 25.400 | 2.00 | 5.00 | 7.00 | 8.00 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 30.000 | 2.00 | 4.00 | 7.00 | 8.00 | 10.00 | 12.00 | - | - | 20.00 |

| 30.000 | 2.00 | 5.00 | 7.00 | 8.00 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 31.750 | 2.00 | 5.00 | 7.00 | 8.00 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 50.000 | 2.00 | 5.00 | 7.00 | 8.00 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 50.000 | 2.50 | 5.00 | 7.50 | 8.00 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 50.000 | 2.50 | 6.00 | 7.50 | - | - | - | - | - | 20.00 |

| 50.000 | 3.00 | 8.00 | 10.50 | - | - | - | 15.50 | - | 20.00 |

| 50.800 | 2.00 | 6.00 | 7.00 | - | - | - | - | - | - |

| 50.800 | 2.00 | 8.00 | 8.00 | - | - | - | - | - | - |

| 50.800 | 2.50 | 6.00 | 7.50 | - | - | - | - | - | 20.00 |

| 50.800 | 2.50 | 8.00 | 10.00 | - | - | - | 15.00 | - | 20.00 |

| 50.800 | 3.00 | 8.00 | 10.50 | - | - | - | 15.50 | - | 20.00 |

| 50.800 | 4.00 | 8.00 | 12.00 | - | - | - | - | - | - |

| 60.000 | 2.50 | 5.00 | 7.00 | 8.00 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 60.000 | 2.50 | 5.00 | 7.50 | 8.50 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 70.000 | 4.00 | 7.00 | 12.00 | - | - | - | - | - | - |

| 75.000 | 2.50 | 5.00 | 7.50 | 8.50 | 10.00 | 12.00 | 15.00 | 17.50 | 20.00 |

| 75.000 | 2.50 | 8.00 | 10.00 | - | 10.00 | - | 15.00 | - | 20.00 |

| 100.000 | 3.00 | 8.00 | 10.50 | - | 10.50 | - | 15.50 | - | 20.00 |

Availability of Eye-Flex® with spacer sleeves

Spacer sleeves as spacers are not considered standard.

Please contact Wire Belt Technical Sales if you require a belt with sleeves as a method of gap spacing.

Materials Available;

- Stainless Steel 1.4301 (304) or 1.4571 (316Ti)

- Mild Steel

Sprocket Pitch Diameter Table

Sprocket Pitch Diameter Table |

|||||||||||

Number of Teeth |

Belt Pitch mm |

||||||||||

15.875 |

25.00 |

25.40 |

30.00 |

31.75 |

50.00 |

50.80 |

60.00 |

70.00 |

75.00 |

100.00 |

|

7 |

36.60 |

57.60 |

58.50 |

69.10 |

73.20 |

115.20 |

117.10 |

138.30 |

161.30 |

172.90 |

230.50 |

10 |

51.40 |

80.90 |

82.20 |

97.10 |

102.80 |

161.80 |

164.40 |

194.20 |

226.50 |

242.70 |

323.60 |

12 |

61.30 |

96.6 |

98.10 |

115.90 |

122.70 |

193.20 |

196.30 |

231.80 |

270.50 |

289.80 |

386.40 |

14 |

71.30 |

112.4 |

114.20 |

134.80 |

142.70 |

224.70 |

228.30 |

269.60 |

314.60 |

337.10 |

449.40 |

15 |

76.40 |

120.2 |

122.20 |

144.30 |

152.40 |

240.50 |

244.30 |

288.60 |

336.70 |

360.70 |

481.00 |

16 |

81.40 |

128.2 |

130.20 |

153.80 |

162.70 |

256.30 |

260.40 |

307.60 |

358.80 |

384.40 |

512.60 |

18 |

91.40 |

144.0 |

146.30 |

172.80 |

182.80 |

287.90 |

292.60 |

345.50 |

403.10 |

431.90 |

575.90 |

20 |

101.50 |

159.8 |

162.40 |

191.80 |

203.00 |

319.60 |

324.70 |

383.60 |

447.50 |

479.40 |

|

Sprocket Material

Available material types include:

- PA6G (Polyamide Cast Nylon 6) - FDA approved.

- POM (PolyOxyMethylene / Acetal) – FDA approved.

- 1.4305 Stainless Steel - standard

- 1.4404 Stainless Steel - for corrosive environments

- Mild Steel

- Other materials on special request.