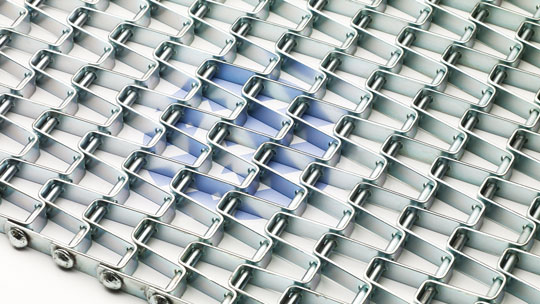

Honeycomb belting, also known throughout the industry as Flat Wire belting, is a straight-running belt with an extremely high strength-to-weight ratio. It is available in a wide variety of aperture configurations to suit applications as diverse as casting, baking, drainage and packaging.

Honeycomb is constructed from formed flat wire strips connected by cross rods running through the width of the mesh. The rods are finished with either welded button edges or hooked edges.

It is a strong, lightweight, positively driven belt. A large open area makes this belt particularly suitable for processes such as washing, drying, cooling, cooking.

- Open mesh construction for quick drainage and free air circulation

- Flat carrying surface

- Easily cleaned

- Easily joined

- Economical

- High strength to weight ratio

- Positive sprocket drive

Typical Applications

Transport

Cooking

Heating

Drying

Cooling

Drainage

Freezing

Baking

Washing

Weed Clearing

Turf Cutting

Breading

Packaging

Sorting

Recycling

Elevating

De-Elevating

Loading

Harvesting

Canning

Pastuerisation

Painting

Assembly

Proofing

Belt Specifications

Honeycomb belt is available in a wide range of specifications. The examples listed in the following tables are the most common. Belts can be up to 5 metres wide, alternative specifications are available, please contact our Technical Sales Engineers for information.

Belt edges:

|

|

| welded button edge | clinched edge |

Belt Specification Details:

| A | Overall belt width |  |

| B | Cross rod pitch | |

| C | Nominal lateral pitch | |

| D | Cross rod diameter | |

| E | Height of flat strip material | |

| F | Thickness of flat strip material | |

| G | Apertures across belt width |

Standard specifications:

European Standard

| Cross Rod Pitch (mm) | Nominal Lateral Pitch (mm) | Flat Strip (mm) | Cross Rod (mm) | |

| ES001* | 13.7 | 14.6 | 10x1 | 3 |

| ES 003 | 26.2 | 15.55 | 12x1.2 | 4 |

| ES 004 | 27.4 | 15.7 | 9.5x1.25 | 3 |

| ES 006 | 27.4 | 24.7 | 9.5x1.25 | 3 |

| ES 012 | 28.6 | 15 | 9.5x1.25 | 3 |

| ES 013 | 28.6 | 26.25 | 9.5x1.25 | 3 |

| ES 015 | 28.4 | 22.5 | 15x1.2 | 4 |

* available button edge (welded washer) only

Imperial Standard

| Cross Rod Pitch (mm) |

Nominal Lateral Pitch (mm) |

Flat Strip (mm) | Cross Rod (mm) |

|

| IS 101A* | 12.85 | 14.48 | 9.5x1.2 | 3 |

| IS 101B* | 13.72 | 14.48 | 9.5x1.2 | 3 |

| IS 101C* | 14.22 | 15.46 | 9.5x1.2 | 3 |

| IS 102A | 28.58 | 15.46 | 9.5x1.2 | 3 |

| IS 102B | 27.53 | 15.22 | 9.5x1.2 | 3 |

| IS 102C | 26.97 | 15.22 | 9.5x1.2 | 3 |

| IS 103 | 28.58 | 26.19 | 9.5x1.2 | 3 |

| IS 104 | 26.97 | 17.78 | 12.7x1.6 | 4.9 |

| IS 105 | 26.97 | 25.4 | 12.7x1.6 | 4.9 |

| IS 106 | 28.58 | 25.4 | 15.9x1.6 | 4.9 |

| IS 107 | 38.1 | 38.1 | 15.9x1.6 | 4.9 |

| IS 108 | 50.8 | 50.8 | 15.9x1.6 | 4.9 |

| IS 109 | 76.2 | 76.2 | 15.9x1.6 | 4.9 |

* available button edge (welded washer) only

Individual Specifications

Apart from the standard sizes above we are able to provide custom built specifications and the table below gives the framework of availability. Please contact our Technical Sales team to discuss availability in detail as further restrictions do apply to flat strip section size required.

| Cross Rod Pitch | Edge Type | |||

| Cross Rod Dia. (mm) | from (mm) | to (mm) | Welded | Clinched |

| 3.00 | 12.7 | 30.0 | • | |

| 4.00 | 13.7 | 29.0 | • | • |

| 5.00 | 25.0 | 28.0 | • | • |

Materials Available

- Stainless Steel 1.4301 (304)

- Stainless Steel 1.4401 (316)

- Stainless Steel 1.4541 (321)**

- Stainless Steel 1.4828**

- Mild Steel

- Galvanised Mild Steel

Honeycomb Drive Components

Sprockets are available in the following sizes:

Table of sprocket pitch circle diameters for European standard drive sprockets

| Belt Standard/Cross Rod Pitch | |||||

| Teeth | ES001 13.7mm |

ES003 26.2mm |

ES004/6 27.4mm |

ES012/13 28.6mm |

ES015 28.4mm |

| 12 | 52.93 | 101.23 | 105.87 | 110.50 | 109.73 |

| 18 | 78.90 | 150.88 | 157.79 | 164.70 | 163.55 |

| 24 | 104.96 | 200.73 | 209.92 | 219.11 | 217.58 |

| 30 | 131.06 | 250.65 | 262.13 | 273.61 | 271.70 |

Table of sprocket pitch circle diameters for imperial standard drive sprockets

| Teeth | Belt Standard/Cross Rod Pitch | ||||||||||

| IS101A 12.85mm | IS101B 13.72mm | IS101C 14.22mm | IS102A 28.58mm | IS102B 27.53mm | IS102C 26.97mm | IS104/5 26.97mm | IS106 28.58mm | IS107 38.1mm | IS108 50.8mm | IS109 76.2mm | |

| 12 | 53.98 | 109.42 | 105.41 | 103.23 | 103.23 | 109.42 | 146.22 | 195.3 | 293.45 | ||

| 16 | 64.58 | 69 | 71.61 | ||||||||

| 18 | 72.39 | 77.52 | 80.72 | 163.09 | 157.1 | 153.87 | 153.87 | 163.09 | 217.96 | 291.08 | 437.36 |

| 24 | 96.34 | 103.12 | 107.39 | 216.97 | 209 | 204.7 | 204.7 | 216.97 | 289.94 | 387.22 | 581.81 |

| 34 | 306.93 | ||||||||||

| 36 | 144.25 | 154.46 | 161.65 | 324.94 | 306.58 | ||||||

Other sprocket sizes are available on request.

Sprocket Material

Available material types include:

- 'Oilon' (Polyamide Cast Nylon 6 - lubricated) FDA approved.

- PA6G (Polyamide Cast Nylon 6) FDA approved.

- Stainless Steel

- Mild Steel

- Cast Iron