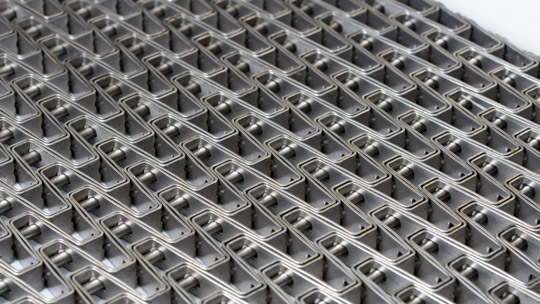

Duplex Honeycomb belting, also known throughout the industry as Duplex Flat Wire belting, is a straight-running belt with an extremely high strength-to-weight ratio. It is available in a single standard specification having a nominal aperture size of 21mm wide x 26mm long.

Duplex Honeycomb is constructed from twin sets of formed flat wire strips connected by cross rods running through the width of the mesh. The duplex arrangement of flat wire strips having a 22.23mm depth produces a very stable belt construction. The cross rods are finished at the edges with a welded washer or nut.

The belt has a very high strength rating and is positively driven by means of specially developed sprockets. The large open area with high strength makes this belt particularly suitable for processes such as the handling of castings or similar in both hot and ambient conditions.

- Open mesh construction for quick drainage and free air circulation

- Flat carrying surface

- Easily cleaned

- Easily joined

- High strength to weight ratio

- Positive sprocket drive

Typical Applications

Freezing

Blanching

Dewatering

Cooling

Quenching

Pasteurising

Washing

Degreasing

Drying

Industrial Ovens

Heavy Duty Industry

General Conveying

Belt Specifications

Duplex Honeycomb belt is available in a single specification as described below. The belt is available in incremental widths from 300mm to 1537mm wide. Please contact our Technical Sales Engineers with information regarding your application.

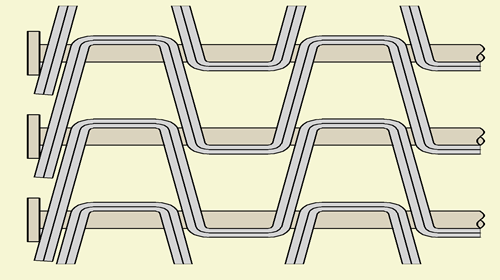

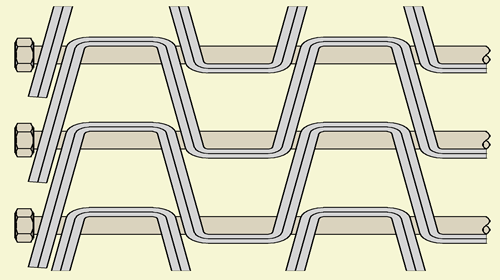

Belt Edges

|

|

| Welded Washer | Welded Nut |

Duplex Honeycomb Belt Data

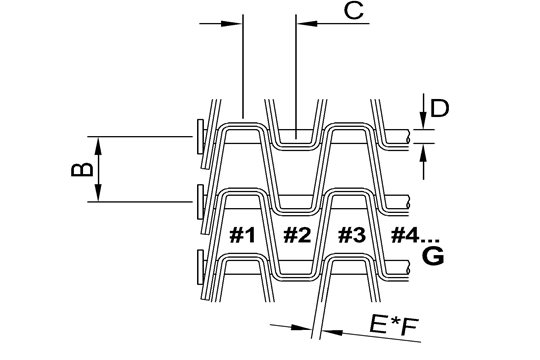

| Belt Code: | IS 125 |

| Specification: | 38.1 - 25.78 (NOM) – 22.23 x 2/2.03 – 7.94 |

| Minimum Width (A): | 300mm |

| Maximum Width (A): | 1537mm |

| Longitudinal Cross Rod Pitch (B): | 38.1mm |

| Nominal Lateral Pitch (C): | 25.78mm nominal |

| Cross Rod Dia (D): | 7.94mm |

| Belt Thickness (E): | 22.23mm |

| Flat Strip Thickness (F): | 2 x 2.03mm |

| Selvedge Finish: | Welded washer /Threaded with welded nut |

| Nominal Open Area: | 58% |

| Belt Weight: | 48.5 Kg/m² |

| Maximum Belt Pull: | Up to 13391 Kgf/mtr width* |

| Product Loading Capacity: | Up to 610 Kg/m² ** |

| Available Materials: | Mild Steel, Zinc Plated Mild Steel, St/Stl 1.4301 (304) alt. 1.4404 (316L) |

| Operating Temperature Range: | Sub Zero to +700°C |

*Dependent upon operating temperature but can be exceeded if duplex sprockets, having twin rows of teeth, are used to drive in every drive space of the belt.

** Dependent upon material, operating temperature, belt support arrangement and conveyor length.

Duplex Honeycomb Drive Components

The drive sprockets are only available in the following sizes.

Sprocket Data

| No. of Teeth | P.C.D (mm) | Bore | |

| Min (mm) | Max (mm) | ||

| 26 | 313.97 | 44.45 | 152.4 |

| 30 | 362.08 | 44.45 | 203.2 |

| 34 | 410.18 | 44.45 | 254 |

Face width through bore: 40mm or 50mm

Material Availability

Cast Iron, Mild Steel or St/Stl 1.4305 (303)

Sprocket style:

a) Standard Simplex – single tooth row.

b) For very heavily loaded applications sprockets with twin rows of teeth (duplex) may be required. Check with Technical Sales with details of your application