Straight Conveyors - Model 200

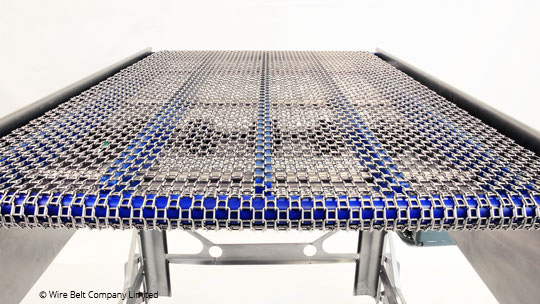

Wire Belt offers a range of straight conveyors designed to ensure efficient operation, improved belt life and maximum cleaning ability. Our straight conveyors feature an open construction with the belt being supported on food grade high density blue polyethylene wear strips clipped to the stainless steel framework.

All our conveyors are suitable for use in hygiene-sensitive environments common to the food and pharmaceutical industries.

Advantages

- Custom-designed to accommodate your specific processing application

- Non-slip, positive drive

- Tight transfers with adjacent conveyors and processing equipment

- Easy to clean and maintain

- Hygienic open structure offering access to all areas for ease of cleaning

- Open section leg frame

- A wide range of optional features ensure versatility to satisfy most requirements

- Can be fitted with various options of conveyor belt to suit your needs

- Stainless steel and UHMW-PE construction

- Height adjustable standard 870 - 1070mm

- Swivel lockable castors are available

- Inclining/declining options available

- Typical belt speeds up to 25 metres per minute*

Our straight conveyors are fitted with Flat-Flex® stainless steel conveyor belting as standard, however alternative belt types are available such as CompactGridTM, Eye-Flex® and Honeycomb. Please speak to our Technical Sales department to select the best belt for your application.

Our standard drive motors and controllers are supplied with IP66 enclosure protection and OS2 surface protection (drive motor only) to ensure suitability for intensive wash down processes. If required, customer specified drive systems can be fitted to suit each individual application.

A variable-frequency drive (VFD) can be fitted alongside the drive motor to provide a stop/start function and speed control. As standard, this is housed inside our Standard Conveyor Control Panel, featuring a fully stainless steel enclosure and emergency stop button. Alternatively, an Invertek E3 Optidrive controller can be supplied with plastic enclosure and no emergency stop function.

As standard. straight conveyors are supplied with height adjustable footpads with fixing holes. As an optional extra, straight conveyors can be supplied with lockable, swivel castors with brakes.

Material

Conveyor Frame construction from stainless steel.

Support surface is high density food grade blue polyethylene.

Available fitted with many different belt options to suit your application

|

|

|

|

|

| Flat-Flex® | Balanced Spiral | Compact-Grid™ | Eye-Flex® | Honeycomb |

Our conveyors can be fitted with many other belting options such as plastic modular, balanced weave and other belting types to suit the needs of your application.