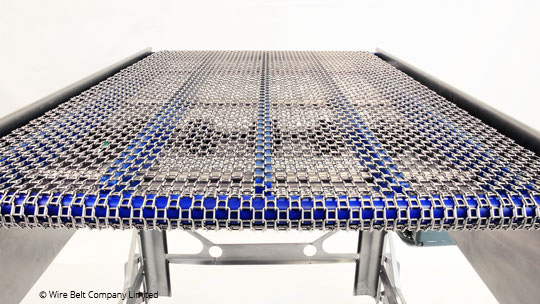

Ladder-Flex™ Conveyor

The necessity to spread, separate or converge products while they are moving on a process belt conveyor is a major requirement for a wide range of food, confectionery and industrial applications. In many cases this allows processors to run narrower conveyors saving factory floor space.

Wire Belt’s answer is a simple positively driven non-slip spreader or converger using Ladder-Flex™ stainless steel belting. The conveyor comprises rows of belting running on a food grade high density blue polyethylene support surface and a series of small stainless steel sprockets driving within the mesh of the belt strands. The conveyors can be custom built to suit the product being handled.

Advantages

- Custom-designed to accommodate your specific processing application

- Non-slip, positive drive

- Tight transfers with adjacent conveyors and processing equipment

- Easy to clean and maintain

- Smooth, gentle product handling for fragile products

- Open section leg frame

- Stainless steel and UHMW-PE construction

- Height adjustable +/- 50mm standard

- Product is fully supported across conveyor surface

- Swivel lockable castors are available

- Alternative drive units

- Inclining/declining options available

- Typical belt speeds up to 25 metres per minute*

Type of configuration:

The standard design is a ‘fan-type’ spreader or converger which positions product evenly on either side of the conveyor centreline.

- Alternatively, chains can be arranged into individual lanes to spread/converge product from specific infeed positions. This configuration is known as a 'lane-type' spreader or converger.

- A variety of other configurations are available to meet other product positioning needs. For example, the left edge orientation could remain constant, while the product spreads toward the right edge.

Our standard drive motors and controllers are supplied with IP66 enclosure protection and OS2 surface protection (drive motor only) to ensure suitability for intensive wash down processes. If required, customer specified drive systems can be fitted to suit each individual application.

A variable-frequency drive (VFD) can be fitted alongside the drive motor to provide a stop/start function and speed control. As standard, this is housed inside our Standard Conveyor Control Panel, featuring a fully stainless steel enclosure and emergency stop button. Alternatively, an Invertek E3 Optidrive controller can be supplied with plastic enclosure and no emergency stop function.

As standard. straight conveyors are supplied with height adjustable footpads with fixing holes. As an optional extra, straight conveyors can be supplied with lockable, swivel castors with brakes.

Material

Conveyor Frame construction from stainless steel.

Support surface is high density food grade blue polyethylene.